Intro to Evo Ventless Griddles

Quite often, big improvements occur when we look at something we took for granted in a new light. Take ventilation systems in commercial kitchens, for example. Traditionally there have always been two assumptions.

Quite often, big improvements occur when we look at something we took for granted in a new light. Take ventilation systems in commercial kitchens, for example. Traditionally there have always been two assumptions.

Not to vent here, but you can't use gas-fired equipment in a ventless environment -- only electric. Why? Good question. Let's look under the hood to find out.

So much time and effort goes into the lead up of a steak coming off the grill. There's the ordering and the prep. There's the menu and the processes that bring it to life. There's even the hiring and training of the staff that will cook it and deliver it. But what about those moments after the steak? What about the important features of your foodservice establishment that don't get all the attention? What about commercial kitchen ventilation?

Saving energy in a restaurant or foodservice operation can lead to greater profitability. In fact, according to ENERGY STAR, restaurants use from five to seven times more energy per square foot than all other types of commercial buildings.

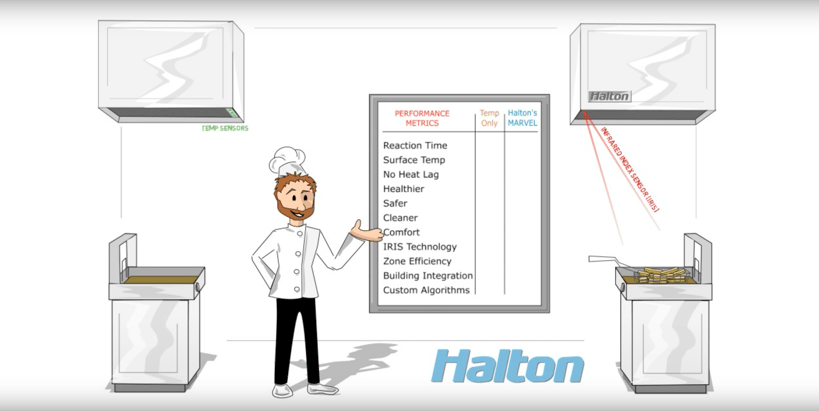

Kitchen ventilation impacts so many parts of a Florida restaurant or foodservice operation. From staff comfort to energy savings, there are many reasons to consider demand control kitchen ventilation. But what does demand control ventilation, specifically Halton's M.A.R.V.E.L. technology, look like when compared directly with temperature-only systems?